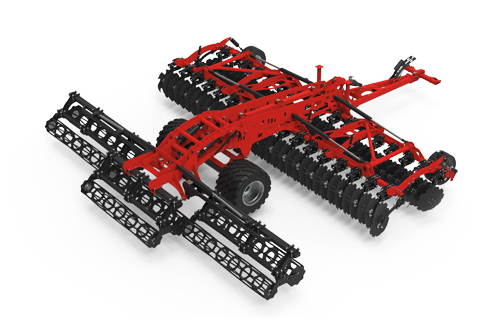

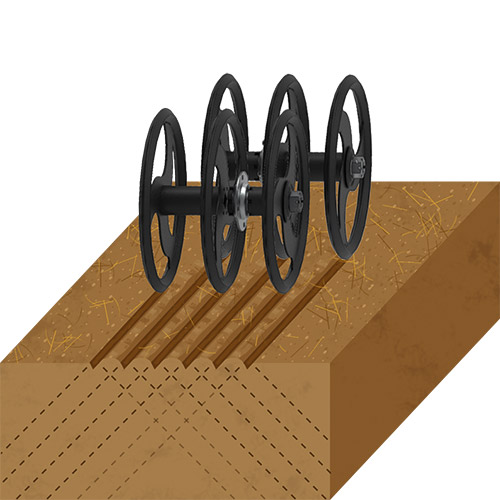

Occitan, the shallow stubble cultivator with large diameter independent discs combining versatility and efficiency

Occitan, the independent disc harrow with high working capacity. A tillage tool designed to reduce your costs thanks to its high working capacity and destruction of plant residues. Integrate your seed drill to increase its agronomic interest and reduce your production costs.

OCCITAN

Shallow stubble cultivator with high capacity independent discs Configure your Occitan

Diversified work with a versatile stubble cultivation tool

A high capacity independent disc harrow to work up to18 cm deep

The Occitan can be used for shallow stubble cultivation after the harvest or for incorporating large volumes of plants, such as grain maize or cover crops.

Shallow stubble cultivation

(France)

Incorporation of grain maize

(France)

Mounted machines with 20 or 32 large diameter discs

Occitan 50

Tractors:

Working width:

Transport width:

Working width:

Transport width:

85 → 210 hp

62,52 → 154,46 kW

2,50 → 4,00 m.

8,20 → 13,12 ft

2,50 → 4,00 m.

8,20 → 13,12 ft

Occitan 60

Tractors:

Working width:

Transport width:

Working width:

Transport width:

125 → 310 hp

91,84 → 228,01 kW

4,20 → 5,20 m.

13,78 → 17,06 ft

3,00 → 3,00 m.

9,84 → 9,84 ft

Occitan T60

Tractors:

Working width:

Transport width:

Working width:

Transport width:

125 → 310 hp

91,84 → 228,01 kW

4,20 → 6,20 m.

13,78 → 20,34 ft

3,00 → 3,00 m.

9,84 → 9,84 ft

Occitan T70

Tractors:

Working width:

Transport width:

Working width:

Transport width:

300 → 450 hp

220,65 → 330,997 kW

7,20 → 8,20 m.

23,62 → 26,90 ft

3,00 → 3,00 m.

9,84 → 9,84 ft

Let’s talk about agronomy...

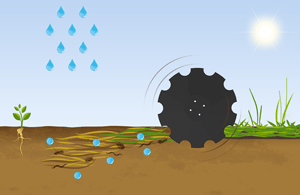

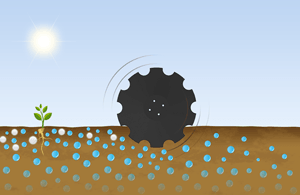

Residue decomposition

The Occitan evenly distributes crop residues and organic matter in the surface layer.The soil is enriched as organic matter is added by the humified residue and earth mixture.

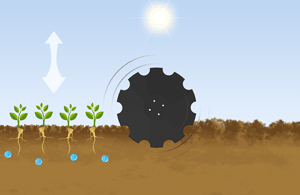

Self-seeding

When the Occitan passes with a depth no more than 5 cm, it creates conditions conducive to weed emergence by encouraging soil-seed contact.Seed stock lifting is dependent on soil moisture and the choice of the roller. Once germinated, a final pass destroys weed emergence and reduces the surface seed stock by about 40%.

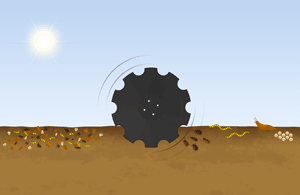

Pest control

The Occitan destroys adult pests and eggs on the surface.Slugs and insects are eliminated by either mechanical action or surface dehydration.

Soil warming

All seeds need balanced conditions to germinate: water, air, heat and soil. With each pass, the Occitan brings moisture from the lower layer and aerates the soil. The soil then warms in the sun.The independent disc harrow thus provides the conditions for rapid germination which in turn means good planting.

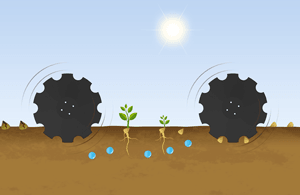

Soil-seed contact

Germination begins when the seed absorbs a large amount of water. For the seed to have access to water, it is important that soil clods surrounding the seed are not too coarse. The seed can take water from the soil when it has good contact with the soil.In order to start photosynthesis, the seed also needs to be in contact with air and light. The soil covering the seed must be loose enough for it to have access to oxygen and for its vertical development in both directions to be unrestricted.

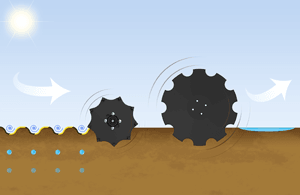

Erosion control

The combined actions of the discs and the Occitan rollers provide excellent soil structuring. By breaking open potential surface crusts, water infiltration and retention capacity is increased.By creating a mulch and leaving behind micro-furrows, Occitan equipment helps to limit erosion. Wind effects are limited, water storage capacity is improved and evaporation is reduced during intercrop periods.

The working part in detail

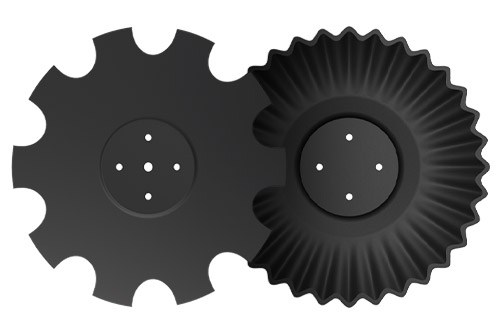

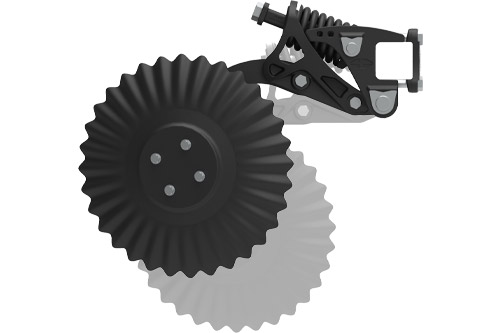

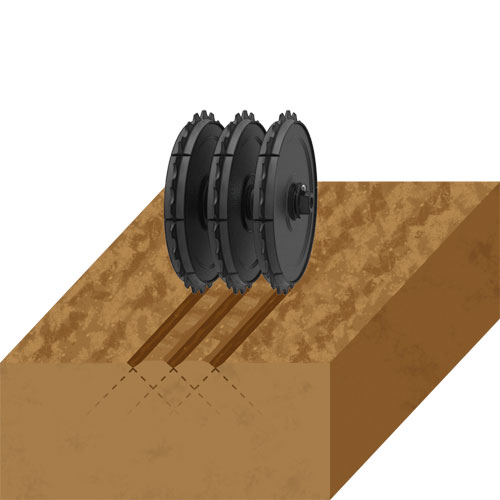

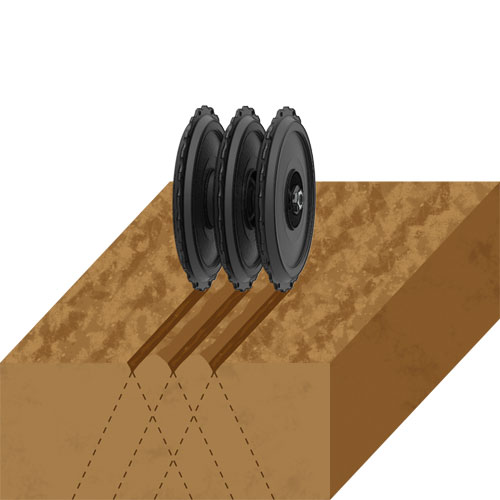

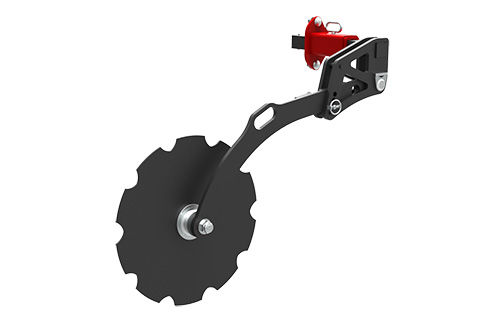

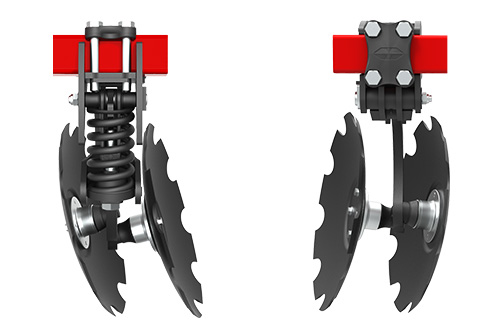

Two discs of large diameter

The Mulcher and big notched discs (Ø 620 mm - 6 mm thick) are self-sharpening and curved, in order to cut properly the plant residues and ensure a homogeneous mix.- Big notched discs: aggressive even in heavy soils or with high quantity of plant residues. Large curve.

- Mulcher discs: cutting and mixing of plant residues.

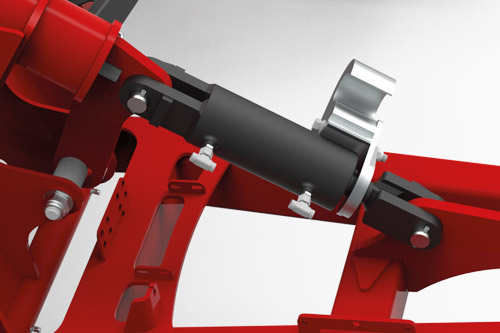

2 discs per arm

Our safety system is designed to accomodate two staggered bearings. The discs have a 230 mm spacing and are perfectly aligned on the whole row. Fitting two discs per arm allows to increase the clearance in the machine and gain in weight and visibility.

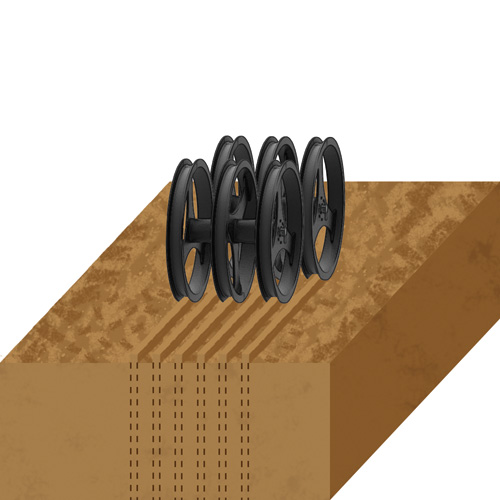

Non-stop spring-loaded safety

Non-stop safety allows you to work without stopping. This system also ensures a very good penetration into the soil.Based on the technology used on the Eurochisel tine (Crossland range), it starts its release at 350 kg, to reach a maximum resistance of 420 kg at 10 cm, then the resistance decreases until 18 cm.

In this way we limit the stresses and shocks on the frame and working elements.

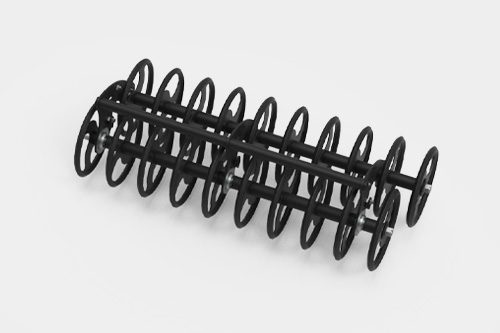

8 different rollers available

Square bar roller

Aggressive on plant residues, this roller creates a homogeneous mulch and accelerates the degradation of stubble while maintaining a good level of moisture in the soil. The roller is light and economical.

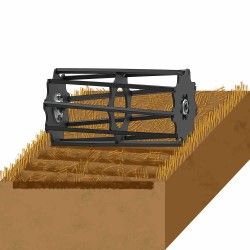

Double square bar roller

Twice as active, it destroys the most resistant plant residues and leaves behind an excellent finish. The unit is mounted on a pivot to conform to the shape of the land.

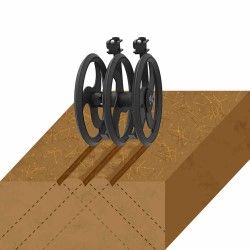

Impak V roller

In wet conditions, the Impak roller consolidates the soil uniformly. The scrapers prevent earth accumulation and level the ground between the passes of stacked rings.

Impak U roller

Impak U Roller (makes furrows)<br>The Impake U roller compresses. Groove-shaped, it is suitable for all dry soils, compared to the Impak V roller it is smaller, lighter and offers less reconsolidation.

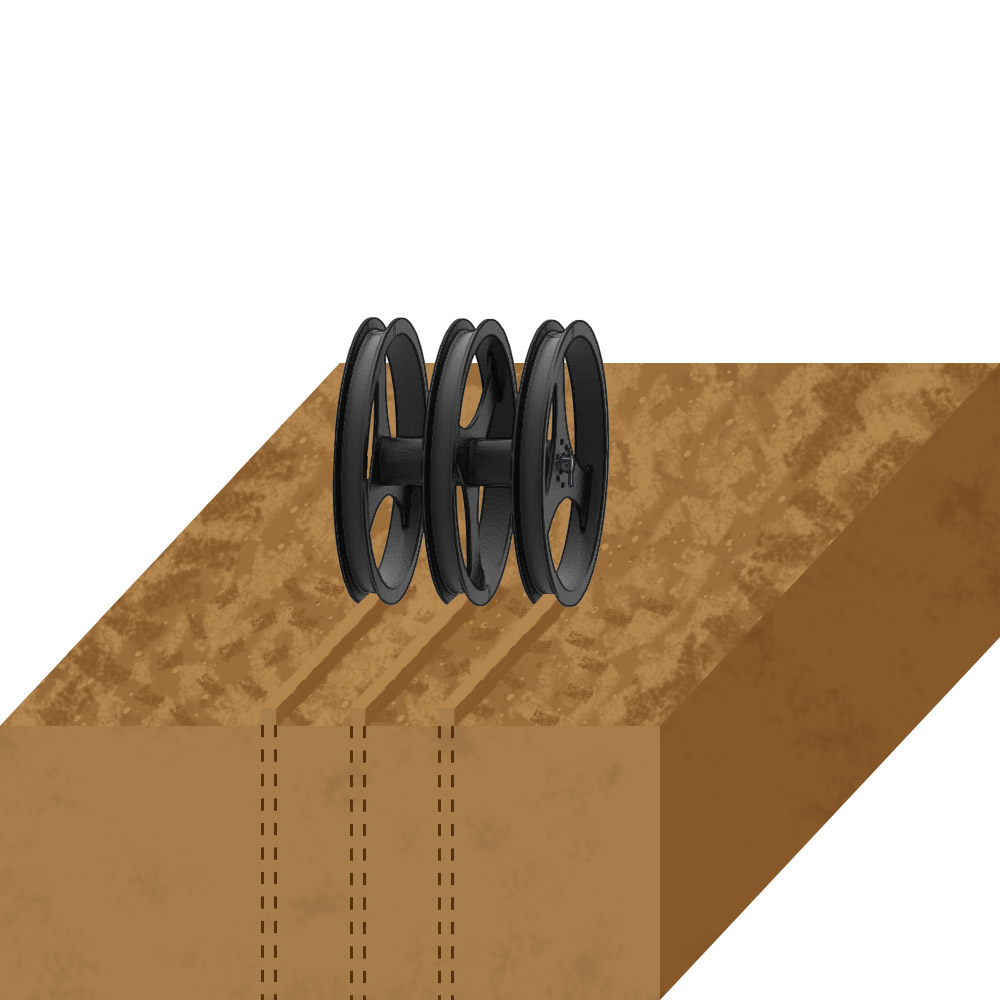

Emopak P roller

The flat-profile Emopak, considered to be a heavy roller, enables shallow compaction. It is ideal for self-seeding. It crushes clods and helps with seedbed preparation to germinate weeds.

Emopak V roller

This roller is made of flanged, V-shaped and notched wheels. The Emopak V’s mass gives you good consolidation, resulting in excellent in-line finishes. For self-seeding, it offers perfect soil/ seed contact. It excels in dry, stony and cloddy soils.

Double roller Impak V

In wet conditions, the Impak double roller helps to consolidate the soil evenly. The bearings are integrated directly into the cage for minimum space between the rollers. Optimised re-crossing ensures homogeneous work.

Double roller Impak U

The double Impak U roller Ø 600 mm provides good load-bearing capacity and earth contact for light to medium-heavy soils. The bearings are integrated directly into the cage for minimum space between the rollers. The optimised re-crossing ensures a homogeneous work.

Key points of the design.

Large clearances

No risk of clogging even with high quantity of plant residues.Spacing between the two disc gangs:

- Occitan 50 / 60: 950 mm

- Occitan T60 :1 100 mm

- Occitan T70 :1 350 mm

Underbeam clearance: 725 mm

Maintenace-free bearings

Sealing and lubrication are reinforced on the bearings of the Occitan range. With a spacing of 230 mm, the bearings have a large support surface on the disc and ensure a perfect ground contour following. Their costs of use are low as intervention times and maintenance costs are minimal. The bearings are guaranteed 3 years on the whole Occitan range.

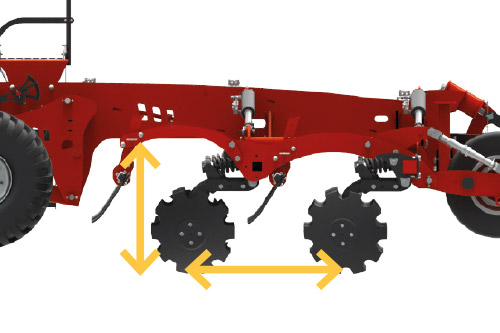

Stabilization wheels

Two front stabilization wheels are available (13,0/55x16 Ø 770 mm), allowing to work at high speed on semi-mounted models. The wheels are adjusted mechanically or hydraulically.

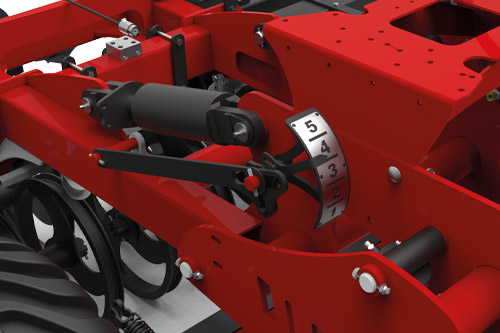

Hydraulic adjustment of the rollers

Hydraulic roller adjustment is standard on semi-mounted models and optional on mounted models. The depth control is effected via the roller and directly from the tractor cabine.

3 harrows

A harrow can be placed after the first disc gang to bring down the flow of soil before the pass of the second disc gang. A second harrow between the rear disc gang and the roller channels the flow. Finally, a third harrow located behind the roller levels the ground.

Deflectors

The lefthand deflector is fitted as standard, the righthand one is optional (strongly recommended). These disc deflectors capture the flow of soil from the outside discs and channel it inside the machine. They are mounted on pivot in order to retract when hitting against obstacle.

Hydraulic compensation on drawbar

The hydraulic drawbar cylinder with shock absorbers makes headland manoeuvres easier. As standard, the cylinder is connected with the lift and lower system of the wheeled carriage, so that only one tractor spool-valve is needed. Depth adjustment at the front is carried out by means of 5 mm thick wedges, ensuring a good precision.

High penetration capacity

The tilt and attack angles ensure for the Occitan range a high penetration capacity even in very dry soil conditions. Both the mounted and semi-mounted models have a high weight per disc, so that work can continue even in unfavourable weather conditions.

Overview

- 1.Non-stop spring-loaded safety and 2 discs pers arm

- 2.Large diameter discs

- 3.High clearance in the machine

- 4.High resistance structure

- 5.8 rollers for different finishes

- 6.Continuous hydraulic roller adjustment

- 7.Easy to use

- 8.Side disc deflectors

- 9.Following harrows to channel the flow

- 10.Maintenace-free bearings

Configure your Occitan www.gregoire-besson.com

Choose your disc harrow according to your tractor power and select the requested options.Sat Feb 14 2026 22:44:31 GMT+0000 (UTC)

Contact

+1 450-253-5615

GB Group Canada

5530 Av., Trudeau

QC J2S 1H4 Saint-Hyacinthe

Canada

Lat., Long.: 45.63649, -72.975388